Achievements in the Nuclear Field

Measuring system for the characterization of high level nuclear wastes

Thanks to our extensive experience in the conception and realisation of custom calorimeters for the nuclear industry, we develop instruments for different sample sizes (from a few ml to 385 l), large power ranges and custom performances.

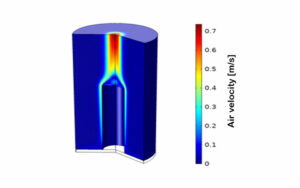

For this specific application we conceived a calorimeter for Sr90/Y90 bearing samples of 0.7 l in volume and generating a thermal power of around 65 W. This high activity of the sample required a special thermal design optimized through numerical simulations.

We also develop high precision calorimeters for the characterization of tritiated samples.

Opposite:Computation Fluid Dynamics simulation of natural convection effects inside the measurment cell promoted by the thermal power generated in the sample.

Automated handling and storage system

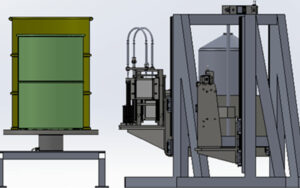

Within the context of post-Fukushima measures, which consist of consolidating or replacing nuclear installations to guarantee their safety eg. in the event of an earthquake or flood, KEP Technologies Group has developed an automated system for handling containers of nuclear material. The automated system enables containers to be stored in racks at different heights while respecting rules to reduce the risk of criticality linked to storage of significant quantities of radioactive material. The KEP Technologies Group managed this complete and complex project from A to Z. It called upon the full technical skills of the group to meet all requirements: safety constraints, earthquake resistance, durability, resistance to radioactive irradiation, easy maintainability, safety redundance, easy handling by operators. The project was carried out in record time for a project of this magnitude. Within its scope the Group’s engineering teams successfully completed: Calculations of earthquake resistance, mechanical studies and design, safety studies, organizational and human factors, etc. design, electrical realization, control command, industrial computing, vision, on-site installation, commissioning, user training, maintenance and logistical support and maintenance (SLI SDF)

Multi-post nuclear sample characterization platform

Opposite: Part of the installation for automated gamma spectrometry testing with a 200 L drum in place for assessment

Multi-measurements laboratory in hot cell environment integrated into the ITER project

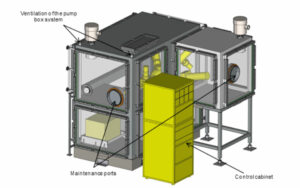

For an application devoted to characterization of radioactive samples, we have conceived a custom multi-platform modular laboratory for installation inside a hot cell.

The laboratory features all the tools necessary for the characterization and analysis of radioactive samples in different forms (dust, smears, metallic objects…).

The system is designed to accomplish different tasks, notably sample transfer between stations, mass and dose rate measurements, elemental composition characterization and radionuclide inventory, gamma cartography and outgassing characterization. All this while ensuring a safe environment for the operator.

Opposite: Detail of the glovebox containing the Secondary-Ion Mass Spectrometry (SIMS) system

Nuclearization of measuring instruments

We offer our expertise for the design, realization and implementation of instruments in gloveboxes for nuclear applications, or other controlled environments for testing purposes.

We provide custom designs according to your requirements and specifications. Beside standard manipulation options, we propose adaptation for automatic systems remotely operated with a manipulator.

We master all regulatory constraints for the conception and installation of gloveboxes in radioactive environments including safety standards and earthquake resistance calculations.

High Temperature Calorimeter installed in an operating glovebox

Would you like more information?

You have a particular problem? Please get in touch with us.